HOW WE MADE OUR NEW BLADES TROPHIES

For the New Blades '17 show we made a series of trophies for the Industry Awards using our Workshop Services

We can combine any of our services to make a whole range of unique products.

Our experienced staff will work with you to on any project you have in mind. Not only do they have a range of services to call upon, next door to the workshop is our shop packed with over 5,500 creative materials.

Contact 020-7264-1294 or workshop@modelshop.co.uk

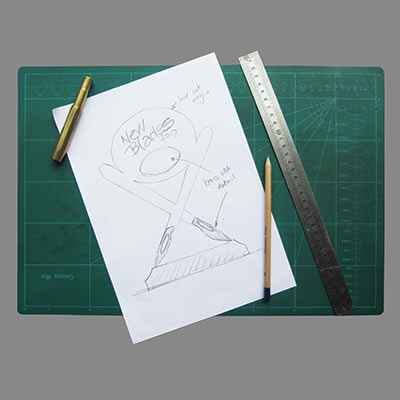

THE NEW BLADES TROPHY PROJECT

It can all start with a simple sketch.

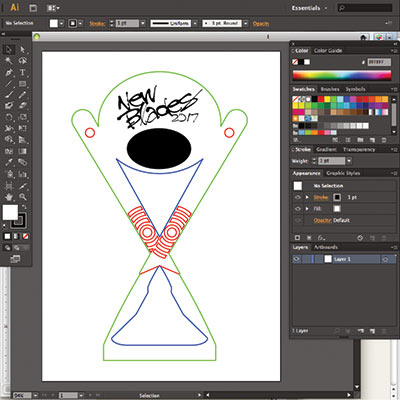

We can convert to a file suitable for laser or any of our Workshop Services.

The top of the trophy laser cut in 4mm clear acrylic.

The bases of the trophy routed from 20mm MDF, sanded and sealed.

The bases were then undercoated with Tetrosyl grey primer.

The bases were then sprayed with Black Satin Spraypaint.

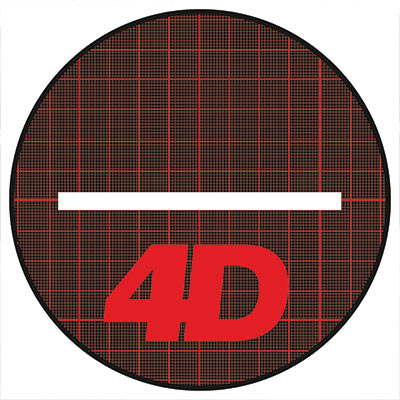

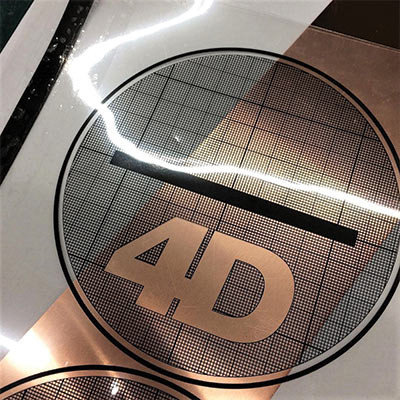

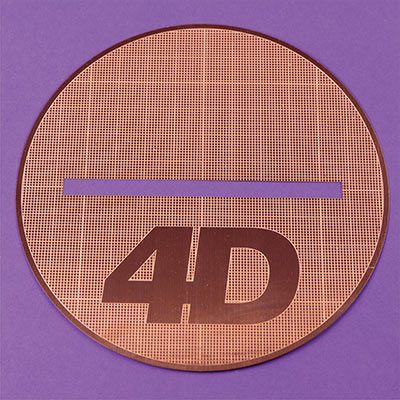

We designed a cover for the base using a cutting mat as inspiration, to be photoetched in copper.

A Photoetching transparency was then made to transfer the design onto the copper sheet.

We then etched the copper using our controlled etching technique which allows us to etch the 4D logo deeper then the grid pattern. This keeps the logo very bold and the cutting mat pattern very crisp.

Next was the photoetching artwork for the scalpel blades and name plaques.

We photoetched the name plaques in copper.

The scalpel blades were etched in nickel silver.

We then assembled the first trophy.

Followed by the other 14.

Finally we needed to assemble 100 graduates in order to find a model maker worthy of such a magnificant prize.